Technology

Technology

We offer comprehensive solutions for remote monitoring of road and off-road trucks, locomotives, diesel generators (gensets), fuel storages and tanks, and other diesel engine machinery. Major parameters monitored include: fuel consumption, time and engine operation mode, volume and temperature of fuel, operation of attached equipment, as well as axle load.

Our technology partner, Technoton, telematics solutions allow machinery owners and operators dramatically improve efficiency of operation and decrease costs.

Our expertise:

- Fuel consumption monitoring of diesel engines.

- Monitoring of stationery and movable/mobile fuel tanks

- Contactless reading and analysis

- Data integration into telematics and GPS/GLONASS monitoring systems.

- Integration of standard analog sensors into telematics systems

- Monitoring of subject’s parameters 24/7 in real-time

The products are designed using technologies employing edge/fog computing methods, which ensure accurate parameter measurement, scalability of telematics system, reliable operation, and guaranteed compatibility of the equipment.

Technology Partner:

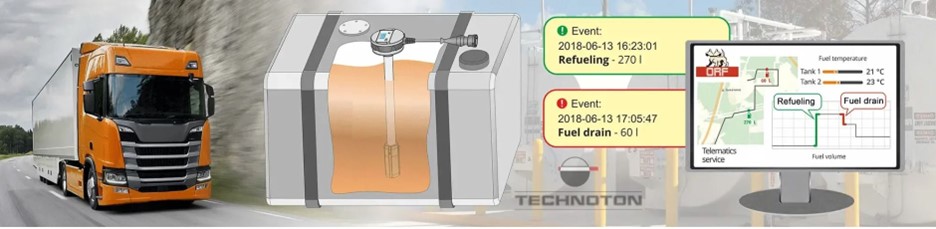

Fuel Tank Monitoring

Many vehicles telematics and stationary object monitoring systems provide fuel tank monitoring features. Quite often, fuel level measurement is one of the core fleet’s requirements to GPS vehicle tracking system for trucks, construction, and agricultural equipment. Moreover, information on fuel volume fill ups and fuel draining volumes from tank or storage is useful for telematics systems of vessels and railroad machinery – equipment with high fuel consumption. Increasingly, fuel level measurement and remote monitoring are implemented for diesel power generator sets, heating equipment rooms and corporate gas stations.

Fuel tank monitoring allows fleet manager or machinery supervisor to:

- Measure precise volumes of fuel tank refill.

- Detect fuel siphoning from fuel tank.

- Prevent fuel theft from tanks (e.g., underfilling or siphoning).

- Reveal fuel mixed with extraneous liquids (e.g., waste oil).

- Compare the fuel quality of different suppliers/gas stations.

- Indirectly define fuel consumption.

- Schedule supply tank refill of stationary engine.

Fuel Consumption Monitoring

Fuel consumption monitoring for vehicles and stationary objects allows a machinery-owner or fleet operator to solve several tasks:

- Optimizing machinery operation modes

- Engine hours and machinery downtime monitoring

- Recalculation of fuel consumption quotas

- Fuel theft prevention.

- Prediction of maintenance date

To achieve optimal operating mode of vehicles:

- A driver can select resource-saving operation mode of engine by using RPM and fuel rate data.

- A mechanic can monitor fuel consumption information using an online telematics system, remotely supervise technical condition of engine and fuel system, schedule technical maintenance taking into account operating conditions of the equipment.

Almost any fleet owner faces fuel theft during vehicle or stationary machinery operation. The highest percentage of fuel misuse occurs with construction, agricultural and other machines, where fuel is accounted according to engine hours. Fuel tank draining, underfilling fuel in a tank, fraud with cash vouchers and fuel cards are the most common methods of fuel theft. They can be eliminated by introducing a fuel consumption monitoring system.

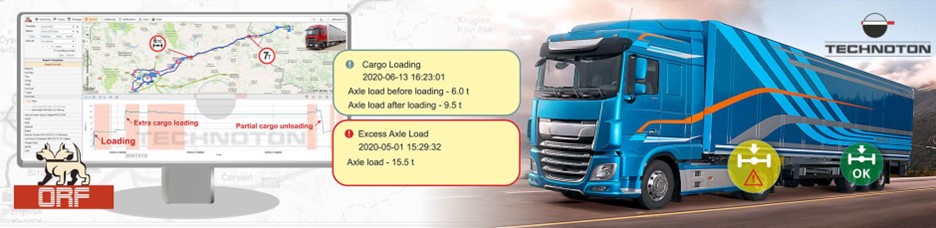

Axle Load Monitoring

Axle load monitoring is useful for vehicle fleets for several reasons. Firstly, exceeding axle load may result in fine for overloading when vehicle stops at weighing station. Secondly, loading vehicle more than axle load limit defined by data sheet shortens vehicle’s life cycle – early breakdown and extra costs for repairing suspension system and vehicle body, higher load on engine and increased fuel consumption.

From the other hand, under-loaded vehicle means reduced profitability of transportation and lower profit margins of vehicle owner: a vehicle uses fuel for “self-transportation,” wear out still occurs, driver gets salary irrespective to the amount of cargo in vehicle or semi-trailer.

One of the methods to optimize vehicle load – manual calculation of load per axle. However, the method is labor-intensive, takes much time, and obtained results should be transferred to vehicle telematics system manually as well.

Automated axle load control system is more convenient, accurate and quick way of truck and trailer weighing.

Talk to Our Experts

+606 794 1241

Download Our Brochure

Download (.pdf, 297kB)

Write to Us

sales@d-elektra.com